A key stage of the product development process is the manufacture of your prototype model to verify the design concept.

Although HH Innovations offer vacuum cast, fabricated and 3D Printed (SLS) samples as methods of verifying product design, one of our most powerful development tools is the ability to CNC machine prototypes.

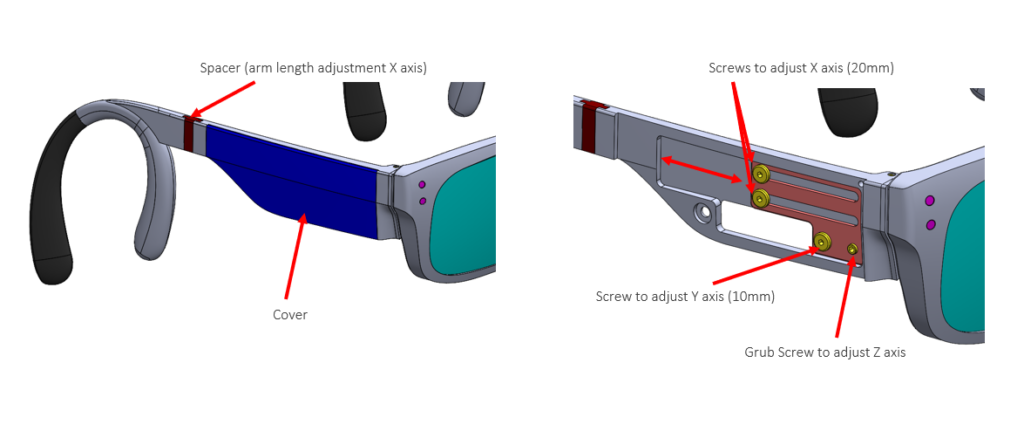

This CNC machined method of prototype manufacture can often be carried out in the production intent material, which can often provide the same / similar colours and surface textures as the finished product. This material will also provide similar properties as the finished material, therefore these prototypes can often be used for testing purposes, if required. The biggest advantage of machined-from-solid prototypes is that they provide the most representative sample of the finished design. CNC prototypes typically have the same aesthetics as the finished product, and are fully functional and are able to be used as if they were the final production item.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

For many the thought of developing a new product may be daunting. For HH Innovations it is our skill.

We have an exceptionally strong development team encompassing wide variety of manufacturing skills that are dedicated to the successful design, development and production of innovative products.

As a strong process driven business, we take products from their concept, along a meticulous advanced quality planning process, through to production and into the continuous supply from our factories.