As well as supporting UK & European manufacturers with product development, tooling, and assembly equipment, HH Group offers a full turnkey subcontract manufacturing service to include product design, tooling design, tooling manufacture, product sampling, production, packaging, and distribution.

We already support a large number of blue chip European clients with our sub contact manufacturing facilities including Aston Martin, McLaren, Jaguar Landrover…and many others.

Our procurement team in Shenzhen have many years’ experience of sourcing Bill Of Materials (BOM’s) lists and can provide additional value to our clients by streamlining and managing their supply chains. They are not simply price focused, but take into account quality, lead times and reliability.

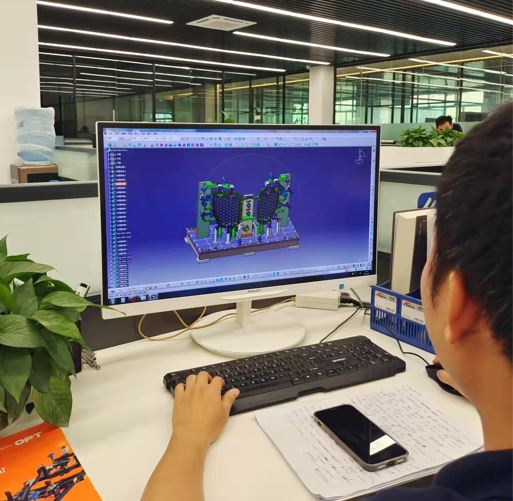

Integrating product design into tool and manufacturing equipment supply is the most streamlined method of eliminating some the errors and delays often encountered when theoretical design data is transferred to actual production process.

Our Design for Manufacture (DFM) process ensures that the product designs are fit for production prior to the manufacture of production tooling.

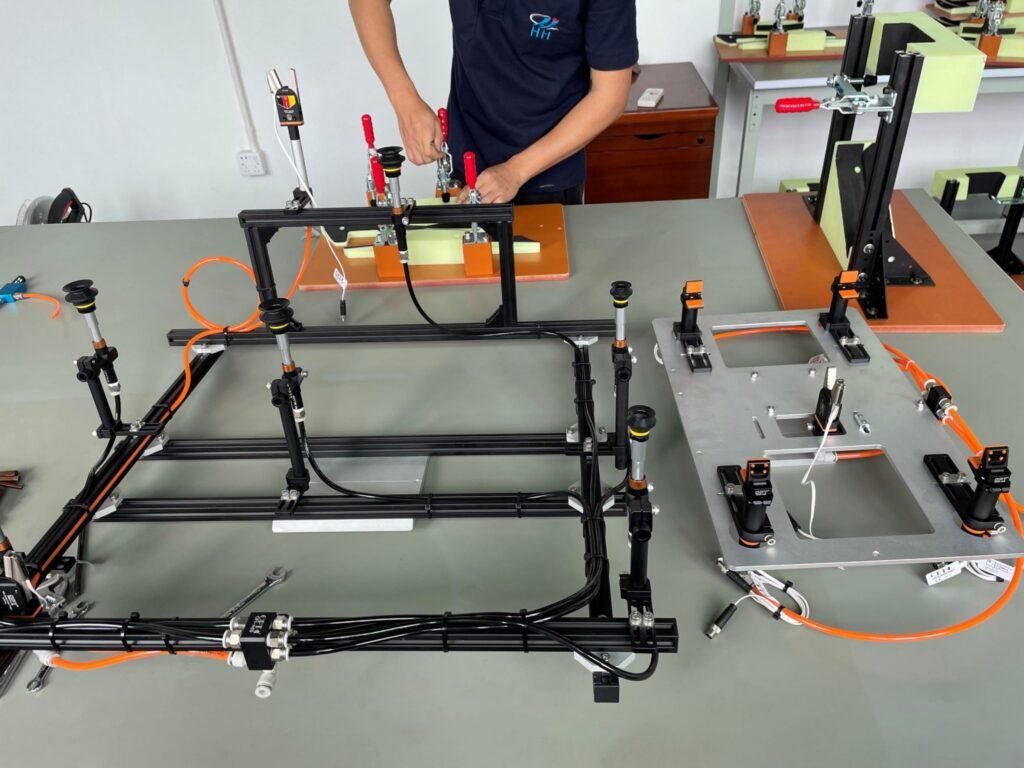

Here at HH Group, we understand that very rarely is an injection moulding tool a stand-alone item. Our tool manufacturing service offers a cell based approach to production of equipment design. We provide End Of Arm tooling (EOAT) designed specifically to assist ease of extraction for the tool. We also provide other secondary operations equipment to include checking and assembly fixtures, IML cassettes and ultrasonic welding tooling and machinery to compliment our injection mould tools.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

For many the thought of developing a new product may be daunting. For HH Innovations it is our skill.

We have an exceptionally strong development team encompassing wide variety of manufacturing skills that are dedicated to the successful design, development and production of innovative products.

As a strong process driven business, we take products from their concept, along a meticulous advanced quality planning process, through to production and into the continuous supply from our factories.

Please contact us for more information