When it comes to bringing your plastic injection moulding project to life, selecting the right product design company can make all the difference. While some companies may specialise in designing products solely for the purpose of capturing intellectual property, it is crucial to consider partnering with an experienced product design company that possesses specific expertise in designing for plastic injection moulding, and manufacture. Here’s why.

Designing for Manufacturing Excellence:

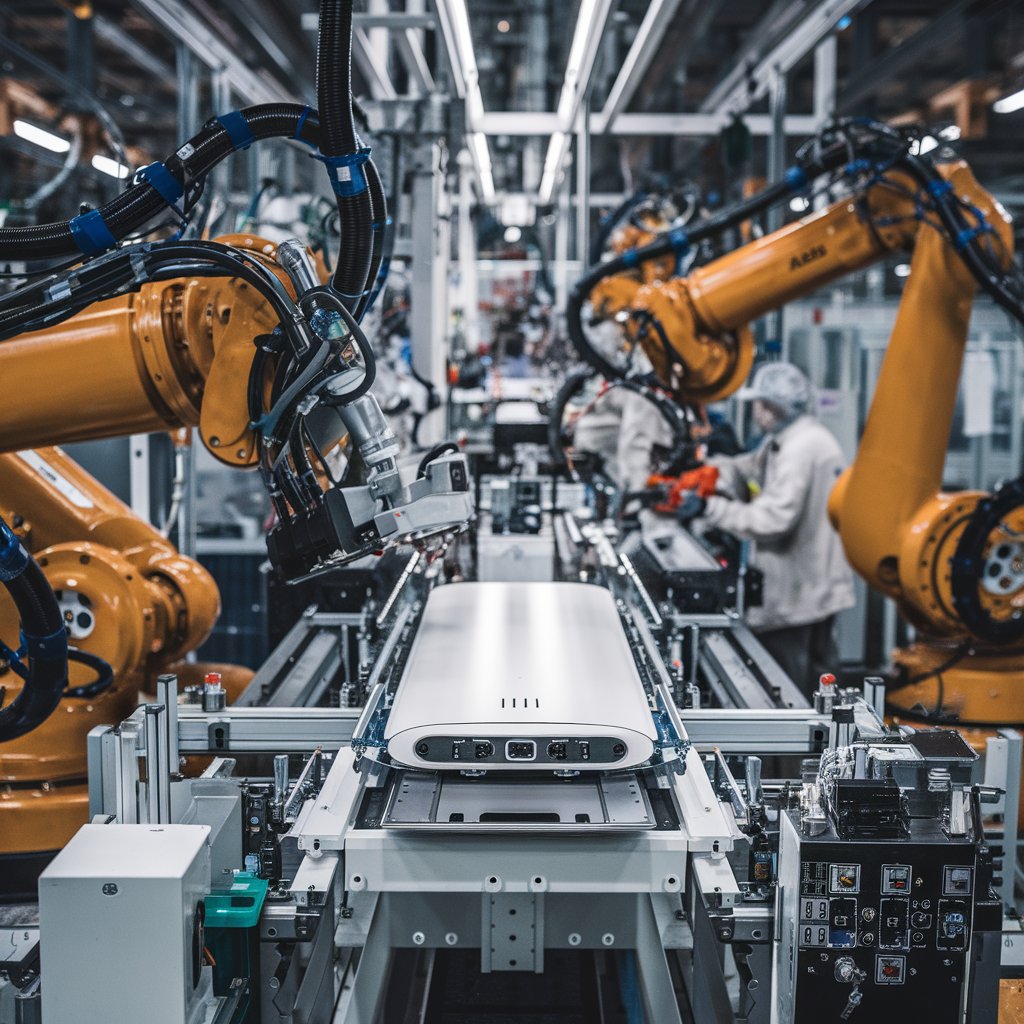

An experienced product design company with a focus on plastic injection moulding understands the intricacies of the manufacturing process. They have a deep knowledge of the capabilities and limitations associated with this manufacturing technique. By collaborating with such a company, you can benefit from their expertise in designing products that are optimised for efficient production, cost-effectiveness, and high-quality output.

Seamless Integration of Functionality and Aesthetics:

Product design is not just about creating visually appealing concepts. It is about ensuring the seamless integration of functionality and aesthetics. A product design company experienced in plastic injection moulding knows how to strike the perfect balance between these two aspects. They can create designs that not only meet your functional requirements but also consider the limitations and possibilities of the manufacturing process. This leads to products that not only look great but also perform optimally once manufactured.

Expertise in Material Selection:

Choosing the right materials for plastic injection moulding is critical. An experienced product design company can guide you in selecting the most suitable materials based on factors such as product functionality, durability, environmental considerations, and cost-efficiency. They are knowledgeable about the various plastic resin options available and can help you make informed decisions that align with your project goals.

Streamlined Development Process:

Working with an experienced product design company that specialises in plastic injection moulding can significantly streamline your development process. Their familiarity with the entire product development cycle, from initial concept to final manufacturing, allows for smoother communication, efficient collaboration, and reduced chances of costly mistakes or delays. This ultimately saves you time, effort, and resources.

Mitigating Manufacturing Challenges:

Designing for plastic injection moulding comes with its own set of challenges. By partnering with a product design company experienced in this field, you gain access to their knowledge of potential pitfalls and best practices. They can proactively identify and address design issues that may impact manufacturability, moldability, or quality. Their expertise helps minimise manufacturing risks and increases the chances of a successful project outcome.

In conclusion, when embarking on a plastic injection moulding project, it is paramount to choose an experienced product design company that specialises in designing for manufacturing. While companies focused on intellectual property capture have their merits, partnering with experts in plastic injection moulding ensures that your product is designed with manufacturing efficiency, functionality, and quality in mind. By leveraging their knowledge and expertise, you can bring your vision to life and achieve the best possible outcome for your project.

For further information or to discuss your plastic injection moulding project, contact HH Innovations, the trusted leader in experienced product design for manufacturing excellence.