At HH Innovations, we’re proud to offer a top-quality prototyping service for all our valued clients.

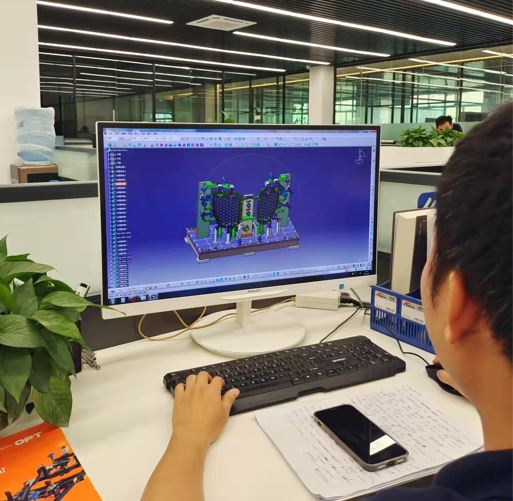

Operating from our facilities in Shenzhen and Dongguan, China, our expert designers and engineers use cutting-edge CAD technology and advanced injection moulding techniques to create flawless prototypes.

Our team meticulously crafts each prototype to meet stringent industry standards, ensuring exceptional quality and precision. We’re dedicated to helping our customers bring their ideas to life, guiding them through every step of the process, from initial concept to final model, making sure your prototype is fully prepared for large-scale production.

Understanding the importance of attention to detail, we adhere to responsible management practices and stringent quality control standards to deliver superior results in every project we undertake.

"Projects from concept through to finished supply of product"

We maintain a responsible controlled management theory, careful Quality Assurance and a professional engineering team in order to provide the best products and after-sales service to customers.

At HH Innovations, we offer expert prototyping services that deliver numerous benefits to our clients, including:

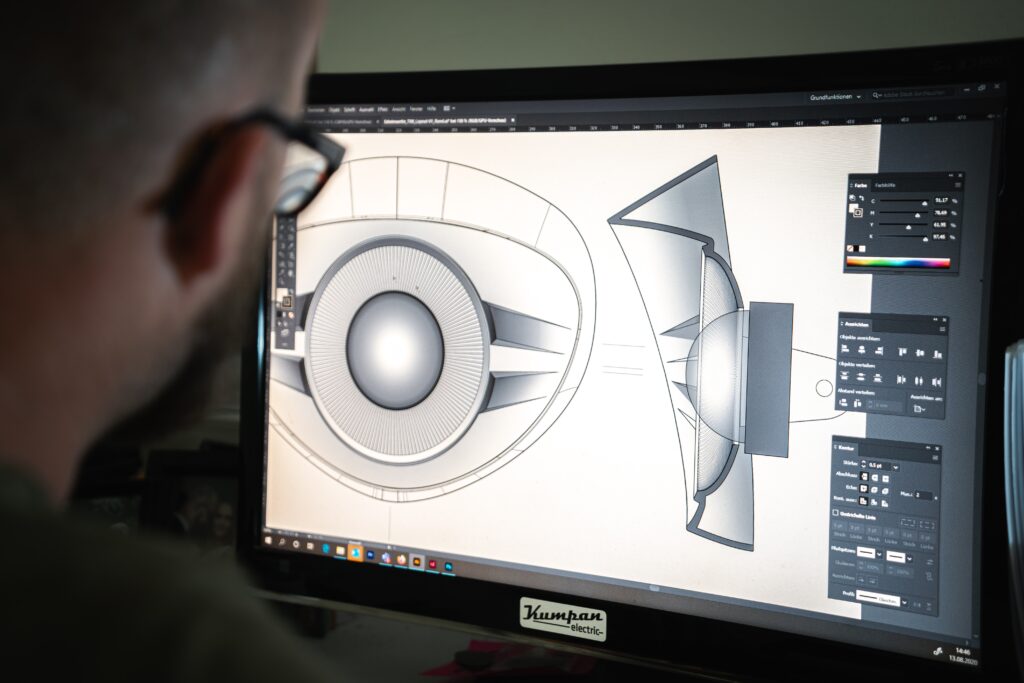

– Access to a team of design and production experts specialising in Computer-Aided Design (CAD) technology.

– State-of-the-art manufacturing facilities in Shenzhen and Dongguan, covering over 10,000 square metres.

– A comprehensive product design service, from initial concept to final production.

– Optional assistance with copyright checks to ensure your product complies with existing trademarks.

– Extensive expertise in product design and manufacturing.

– Adherence to industry-leading quality control standards.

– Implementation of responsible management practices.

Before the prototyping process begins, our team can expertly design your product using cutting-edge CAD technology. Our workforce of over 40 specialist CAD designers offers comprehensive design and support services, from Design for Manufacture reviews to concept realisation.

We believe that all businesses, regardless of size, should have the opportunity to develop high-quality products that succeed in the global market. That’s why we’re dedicated to streamlining design and development timelines by utilising efficient manufacturing processes. This approach reduces waste and ensures fast turnaround rates for superior products.

By minimising the time and resources spent on manufacturing, we can keep costs low for our customers. This allows us to offer high-quality, efficient services that are accessible to businesses of all sizes.

CNC machining allows us to create prototypes using the same materials intended for final production. This means we can match the colours and textures of the final product, ensuring the prototype has properties similar to the finished material, thereby providing more reliable testing results.

CNC machined prototypes will faithfully depict the aesthetics and features of the finished product, and are fully functional and ready for immediate use.

Prototyping is the most exciting stage of product development, as it is where our clients start to see their ideas come to life.

We prioritise early prototyping to avoid wasted resources later in the development process. This approach allows clients to make necessary adjustments before moving to the precision tooling stage, reducing the risk of financial losses from inaccurate tooling. The result is significant cost savings and faster turnaround times.

We produce prototype parts using various methods, including vacuum casting, fabrication, SLS, SLA, and FDM. However, our most popular and effective method is CNC prototype machining.

Our manufacturing and supply services are supported by our expansive facilities, covering over 10,000 square metres in Shenzhen and Dongguan. This significant space allows us to operate with industrial-level production capabilities.

We are dedicated to providing reliable subcontract sourcing, assembly, and finished product supply services, ensuring every product meets your exact specifications and quality standards.

Our Quality Assurance and Quality Control protocols are meticulously designed, drawing from our extensive experience in the product development industry, to guarantee exceptional performance in all our products.

We are proud to have achieved ISO 9001:2015 certification for both the design and manufacture of plastic moulds and accessories, as well as the sales of plastic auto parts. This certification reflects our commitment to maintaining high standards in all our work.

At HH Innovations, we recognise that product development can be costly and time-consuming, and investing in a product that fails due to copyright and trademark issues can be devastating for a company.

That’s why by leveraging our close connections with expert patent specialists, we can ensure your product complies with copyright and trademark laws before production begins. This way, you will be fully aware of any potential issues early on, allowing you to make necessary adjustments before further investment.

Plus, if any copyright or trademark issues do arise, we will work with you to find the best solution.

HH Innovations is a proud member of the HH Group, established in 2013.

With our headquarters at the University of Lincoln in the UK, and manufacturing facilities in the bustling economic hubs of Shenzhen and Dongguan, China, we excel in delivering top-quality design and production services. Our esteemed clients span various industries, including Consumer Electronics, Home Appliances, Automotive, Hospitality, and Medical.

Our mission is to help clients from all professional backgrounds create fully finished, market-ready products that succeed globally. Whether you’re an independent entrepreneur or a small to medium-sized business, our skilled team of production experts is here to bring your creations to life.

We provide comprehensive services and outstanding customer support to ensure exceptional results, helping our clients and their product ideas reach their full potential.

We take pride in being a trusted supplier of product development and production services across many sectors, committed to delivering superior-quality services at cost-effective prices for our valued clients.

HH Innovations is a proud member of the HH Group, established in 2013. With our headquarters at the University of Lincoln in the UK, and manufacturing facilities in the bustling economic hubs of Shenzhen and Dongguan, China, we excel in delivering top-quality design and production services. Our esteemed clients span various industries, including Consumer Electronics, Home Appliances, Automotive, Hospitality, and Medical.

Our mission is to help clients from all professional backgrounds create fully finished, market-ready products that succeed globally. Whether you’re an independent entrepreneur or a small to medium-sized business, our skilled team of production experts is here to bring your creations to life.

We provide comprehensive services and outstanding customer support to ensure exceptional results, helping our clients and their product ideas reach their full potential.

We take pride in being a trusted supplier of product development and production services across many sectors, committed to delivering superior-quality services at cost-effective prices for our valued clients.

We offer prototyping services across a large number of industries, including Consumer Electronics, Home Appliances, Automotive, Hospitality, Medical, and more.

To learn more about how our specialist prototyping services can benefit your industry, email us at innovations@hhplastic.net or call us at 0800 246 5920. We aim to respond to all queries within 24 hours.

We offer prototyping services across a large number of industries, including Consumer Electronics, Home Appliances, Automotive, Hospitality, Medical, and more.

To learn more about how our specialist prototyping services can benefit your industry, email us at innovations@hhplastic.net or call us at 0800 246 5920. We aim to respond to all queries within 24 hours.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |