At HH Innovations, as one of the UK’s top medical device design companies, we know that effective design, development, and manufacturing processes are crucial for achieving the best outcomes for patients needing specialised medical care.

Whether it’s technology for intensive care units or prosthetics for everyday use, medical devices play a vital role in improving the success rates of procedures and surgeries, and in enhancing the quality of life for patients with chronic health conditions.

In our industry, strict quality control and precision are essential to produce high-quality medical technologies. These technologies help healthcare facilities deliver excellent care, and must undergo rigorous testing to ensure they meet all necessary standards.

We fully appreciate the responsibility of creating high-quality parts for the medical field, and are honoured to support the dedicated healthcare workers on the front lines.

"Projects from concept through to finished supply of product"

We maintain a responsible controlled management theory, careful Quality Assurance and a professional engineering team in order to provide the best products and after-sales service to customers.

Designing, developing, prototyping, and manufacturing medical devices are highly specialised tasks that require a deep understanding of the medical industry to produce top-quality products.

These processes involve several key steps, including:

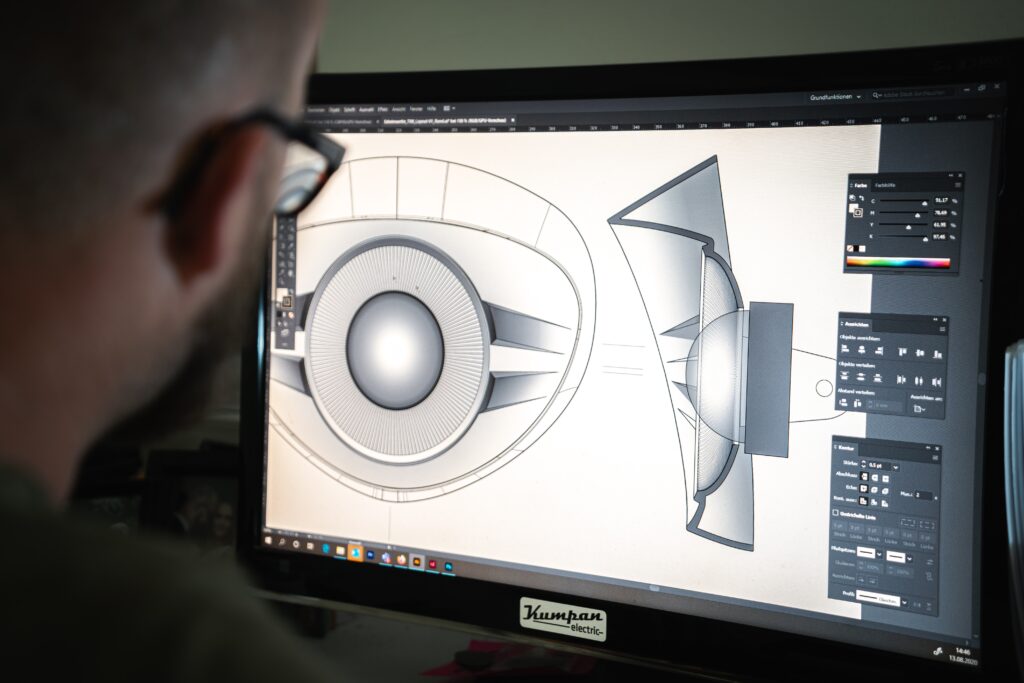

User-Centric Design

Clinicians and patients need to be deeply involved in the design process to ensure the final product is usable, ergonomic, and safe. This means working closely with medical specialists, and using focus groups of medical professionals and patients to gather their personal experiences and specific needs – such as ergonomic design or pain reduction, for example.

At HH Innovations, we prioritise feedback from our clients to ensure that both clinician and patient experiences shape our designs. This approach leads to medical devices that are not only safe and usable but also comfortable for patients, promoting high standards of care in the healthcare sector.

Regulatory Compliance

At HH Innovations, we ensure our designs meet all regulatory standards and thoroughly document every step of the process. Our extensive experience with regulatory requirements includes in-depth research and consultations with industry professionals to uphold these standards throughout the design stage.

Innovation

Medical device development is continually advancing due to technological innovations. These advancements allow manufacturers to create high-quality devices that improve patient care and healthcare outcomes.

At HH Innovations, we are dedicated to using data-driven technologies to develop superior medical devices that meet the needs of healthcare providers and the patients they serve.

Feasibility And Risk Assessment

We focus on technical feasibility and thorough risk assessments to ensure our designs are practical, and – most importantly – safe for patients and medical staff.

We make sure our designs are achievable within the set timeline and budget, streamlining our processes to keep costs low for medical providers. Our risk assessment process helps us identify and minimise potential risks before the prototyping stage, reducing costs and enhancing efficiency later on.

Interdisciplinary Collaboration

During development, we continue to work closely with medical specialists, using continuous feedback loops to ensure our products meet their needs.

This collaboration guarantees that our devices are technically sound and effectively serve healthcare professionals and patients. Plus, we ensure that a variety of stakeholders are consulted throughout the design and development stages.

Regulatory Pathway Planning

At HH Innovations, we engage with regulatory bodies from the early stages of development to ensure our devices meet all relevant standards and requirements. Then, we plan and conduct clinical trials, making sure our designs are data-driven and meet the needs of staff and patients.

Throughout this process, we maintain clear and transparent communication with regulatory authorities. By prioritising regulatory pathway planning, we ensure our devices are market-ready and fully compliant with all industry regulations.

Prototyping is a crucial stage in developing medical devices. This process involves creating a prototype of the final product to undergo rigorous testing and verification, ensuring it is safe and functional before moving to manufacturing.

Our prototyping process allows us to test medical device designs early, identifying and resolving potential flaws. We emphasise early-stage prototyping to avoid wasting resources and to ensure a smoother development process.

This allows clients to make necessary adjustments before precision tooling, reducing the risk of financial losses. Our approach leads to significant cost savings and faster turnaround times, which is essential in the high-pressure medical industry.

At HH Innovations, we use various methods to produce medical device prototypes, including vacuum casting, fabrication, SLS, SLA, FDM, and CNC prototype machining.

Scalability And Efficiency

Scalability and efficiency are crucial in our manufacturing process. We use advanced automation techniques to scale up production without compromising quality. This ensures we can grow while keeping costs down and maintaining product consistency.

Quality Control

During quality control, we thoroughly test at every stage of manufacturing to meet stringent regulatory standards. Our strict compliance ensures our medical devices are safe, effective, and reliable.

Meanwhile, our quality control protocols include regular inspections, rigorous testing, and validation processes to identify and resolve any issues before the device reaches the market.

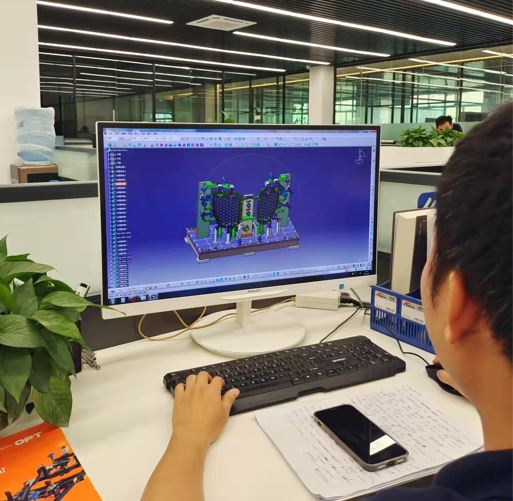

Manufacturing

At HH Innovations, we proudly partner with our sister company HH Plastics, specialists in plastic injection moulding with extensive facilities in Shenzhen and Dongguan, China. This partnership provides our clients with access to a highly experienced team and over 10,000 square meters of production space.

Through this arrangement, we can offer sub-contract sourcing, assembly, and finished product supply services, ensuring each product meets our clients’ specifications and quality standards.

CNC Prototyping For Medical Devices

CNC machining enables us to create prototypes using materials that closely resemble the final product. This means our prototypes will have the same or similar colours, textures, and properties as the finished device, leading to more reliable testing results.

In the medical industry, designs must meet all necessary specifications. For instance, we can produce prototypes in various skin tones for prosthetics, ensuring they meet aesthetic and functional requirements.

Our CNC-machined prototypes accurately reflect the final design and are ready for rigorous medical testing right away, without needing further adjustments or enhancements.

CNC machining enables us to create prototypes using materials that closely resemble the final product. This means our prototypes will have the same or similar colours, textures, and properties as the finished device, leading to more reliable testing results.

In the medical industry, designs must meet all necessary specifications. For instance, we can produce prototypes in various skin tones for prosthetics, ensuring they meet aesthetic and functional requirements.

Our CNC-machined prototypes accurately reflect the final design and are ready for rigorous medical testing right away, without needing further adjustments or enhancements.

At HH Innovations, we take pride in our rigorous Quality Assurance and Quality Control measures across our design, development, prototyping, and manufacturing processes, having developed these measures based on our extensive expertise in product development.

We are proud to hold ISO 9001:2015 Certification for the Design and Manufacture of Plastic Moulds and Accessories, and are dedicated to maintaining these standards by consistently applying stringent Quality Assurance and Quality Control measures throughout our operations.

At HH Innovations, we take pride in our rigorous Quality Assurance and Quality Control measures across our design, development, prototyping, and manufacturing processes, having developed these measures based on our extensive expertise in product development.

We are proud to hold ISO 9001:2015 Certification for the Design and Manufacture of Plastic Moulds and Accessories, and are dedicated to maintaining these standards by consistently applying stringent Quality Assurance and Quality Control measures throughout our operations.

At HH Innovations, we take pride in being part of the HH Group, established in 2013. Our team of experts specialises in product design, manufacturing, and injection moulding processes, harnessing cutting-edge design and production facilities to create premium-quality products for our global clients.

Our headquarters are based in the UK under the leadership of our experienced management team, with manufacturing facilities based in the economic hubs of Shenzhen and Dongguan, China.

We excel in delivering high-quality design and production services, with a strong focus on catering to blue-chip companies across diverse industries such as the Medical, Consumer Electronics, Home Appliances, and Automotive sectors.

At HH Innovations, we take pride in being part of the HH Group, established in 2013. Our team of experts specialises in product design, manufacturing, and injection moulding, using cutting-edge facilities to create premium-quality products for our global clients.

Our headquarters are in the UK, led by an experienced management team, with manufacturing facilities located in the economic hubs of Shenzhen and Dongguan, China.

We excel in providing high-quality design and production services, focusing on blue-chip companies in industries such as Medical, Consumer Electronics, Home Appliances, and Automotive.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |