HH Innovations: Your Electronics Design Experts!

At HH Innovations, our team of specialists provide an industry-leading electronics design and manufacturing service. We use our expertise in the plastic injection moulding sector to help businesses of all sizes bring their products to life.

Our goal is to ensure that these products are not only well-designed, but also meet the rigorous standards of the industry!

Starting from the initial concept phase and moving through prototype development to mass production, our team possesses the skills and industry knowledge to help clients create high-quality products.

We can tailor our services to meet a wide range of client-specific needs, from our base at the University of Lincoln.

Complementing our operations, we have manufacturing bases in Shenzhen and Dongguan, China. This strategic setup allows us to deliver high-quality products at cost-effective rates.

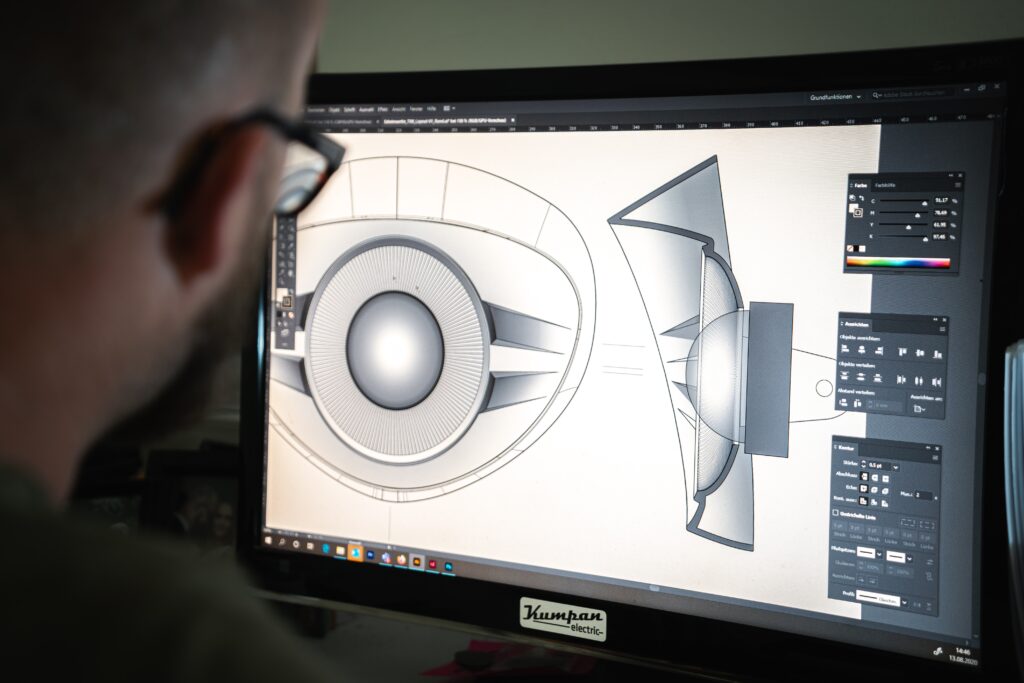

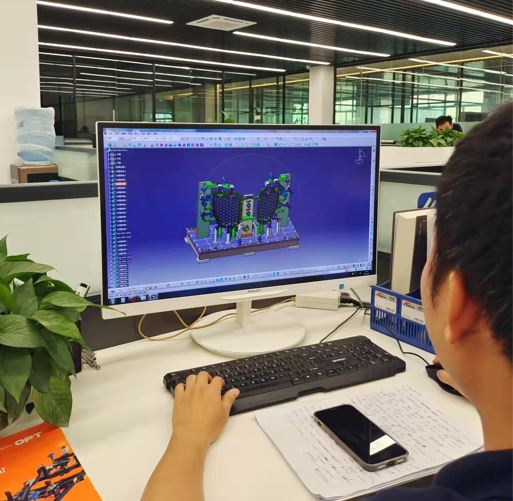

Our manufacturing facility is staffed with a dedicated team of highly trained Computer-Aided Design (CAD) designers and engineers. They harness the power of cutting-edge injection moulding technology from our state-of-the-art facilities to bring our clients’ ideas to life.

We understand the critical need for precision in the electronics industry, particularly when producing intricate parts for industrial use.

That’s why we adhere to responsible controlled management principles and maintain high-quality control standards throughout our processes, ensuring optimal results at every stage.

Our unwavering commitment is to deliver products of exceptional quality that meet the stringent standards of the electronics industry.

We’re here to support you in transforming your designs from initial concepts into perfectly finished, market-ready products!

"Projects from concept through to finished supply of product"

We maintain a responsible controlled management theory, careful Quality Assurance and a professional engineering team in order to provide the best products and after-sales service to customers.

Our services are crafted to set new standards in the global electronics industry.

Here are some of the key benefits we offer to our clients:

At HH Innovations, we’re firm believers that businesses of all sizes deserve the chance to bring their unique product visions to life.

When you partner with HH Innovations, you gain access to a dedicated team of over 40 skilled mechanical designers through our network of partner companies. We offer comprehensive design and technical support services to our clients in the electronics industry, from conducting Design for Manufacture reviews to helping you realise your concepts.

We recognise that in the world of manufacturing, time is a precious commodity. That’s why we’re committed to streamlining design and development processes, blending our expert design service with cutting-edge prototype and production facilities.

The result? An exceptionally efficient manufacturing process that minimises resource wastage and delivers top-notch products with rapid turnaround times.

We recognise that the electronics industry demands precision in both design and manufacturing to produce high-quality, functional products.

To streamline assembly and make tooling more efficient and cost-effective, we start by analysing component designs during the conceptualisation phase. We apply DFM (Design For Manufacture) principles to optimise moldability and reduce the need for secondary operations. This approach minimises wasted resources and guarantees a stellar result.

Our design and manufacturing services adhere to the most stringent standards, harnessing the power of accurate and efficient CAD technologies to craft premium-quality products. We hold your satisfaction and the quality of our work paramount.

Prototyping plays a crucial role in the product development process.

Anticipating potential design issues before creating a prototype can be challenging, yet delaying prototyping until later stages can result in wasted resources. That’s why we offer our clients access to prototyping services early in the product development journey.

Through our prototype service, clients get an initial glimpse of their product, allowing for necessary adjustments before precision tooling is produced. This approach mitigates the risk of financial losses stemming from inaccurate tooling, substantially reducing wasted time and money.

Furthermore, our partners can offer support for producing prototype parts using various methods, such as SLS, SLA, 3D Printing, or casting from silicon moulds or aluminium tools for pre-production runs. We also maintain FDM and SLS 3D printing facilities at our base at the University of Lincoln.

Our Product Manufacturing and Supply Services are supported by well-equipped production facilities, spanning over 10,000 square meters in both Shenzhen and Dongguan. This expansive setup empowers us to deliver industrial-scale production capabilities.

We take immense pride in offering a trusted subcontracting service that encompasses sourcing, assembly, and delivering finished products. We are committed to ensuring that every finished product precisely matches your specifications and meets your quality standards.

Our dedication to quality is reflected in our meticulously crafted Quality Assurance and Quality Control measures. These protocols are the result of our extensive experience in the product development industry, assuring exceptional performance for all our products.

We’re proud to hold an ISO 9001:2015 Certification for both the Design and manufacture of Plastic Mold and Accessories, as well as in the Sales of Plastic Auto Parts. We remain steadfast in upholding these standards across all aspects of our work.

At HH Innovations, we understand the frustration of investing significant resources in product development, only to face copyright and trademark issues that might hinder your product’s marketability.

Unlike less scrupulous manufacturers, our commitment is to ensure that our clients not only have a successful product but also one that’s ready for the market.

To achieve this, we’ve fostered close ties with expert patent specialists. They can help you conduct thorough research to determine if your product runs afoul of any copyright or trademark laws even before production kicks off.

This proactive approach ensures you’re fully informed about any potential conceptualisation issues. And if any problems do arise, we’ll collaborate with you to find the best possible solutions.

Your success is our priority!

At HH Innovations, we’re an integral part of the HH Group, an organisation founded in 2013.

What sets us apart is our team of experts, well-versed in product design, manufacturing, and injection moulding processes. We operate within state-of-the-art design and production facilities, all geared toward creating exceptional products for our global clients.

Our headquarters are located in the UK, and managed by a seasoned leadership team, while our manufacturing hubs are strategically situated in the economic heartlands of Shenzhen and Dongguan, China.

Here, we excel in providing top-tier design and production services, specialising in delivering exceptional products for blue-chip companies spanning industries like Consumer Electronics, Home Appliances, Automotive, Hospitality, and Medical.

Our vision is to support clients hailing from diverse professional backgrounds in bringing their products to market. Whether you’re an independent entrepreneur or represent a small or medium-sized enterprise, we stand by your side throughout the entire production journey.

We take immense pride in our role as a trusted supplier of product development and production services across numerous sectors, remaining steadfast in our commitment to delivering exceptional products at cost-effective prices for all our valued clients.

At HH Innovations, we’re an integral part of the HH Group, an organisation founded in 2013.

What sets us apart is our team of experts, well-versed in product design, manufacturing, and injection moulding processes. We operate within state-of-the-art design and production facilities, all geared toward creating exceptional products for our global clients.

Our headquarters are located in the UK, and managed by a seasoned leadership team, while our manufacturing hubs are strategically situated in the economic heartlands of Shenzhen and Dongguan, China.

Here, we excel in providing top-tier design and production services, specialising in delivering exceptional products for blue-chip companies spanning industries like Consumer Electronics, Home Appliances, Automotive, Hospitality, and Medical.

Our vision is to support clients hailing from diverse professional backgrounds in bringing their products to market. Whether you’re an independent entrepreneur or represent a small or medium-sized enterprise, we stand by your side throughout the entire production journey.

We take immense pride in our role as a trusted supplier of product development and production services across numerous sectors, remaining steadfast in our commitment to delivering exceptional products at cost-effective prices for all our valued clients.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |