Our technical team can draw upon many years’ experience from the multiple disciplines that are required to develop a successful moulded product.

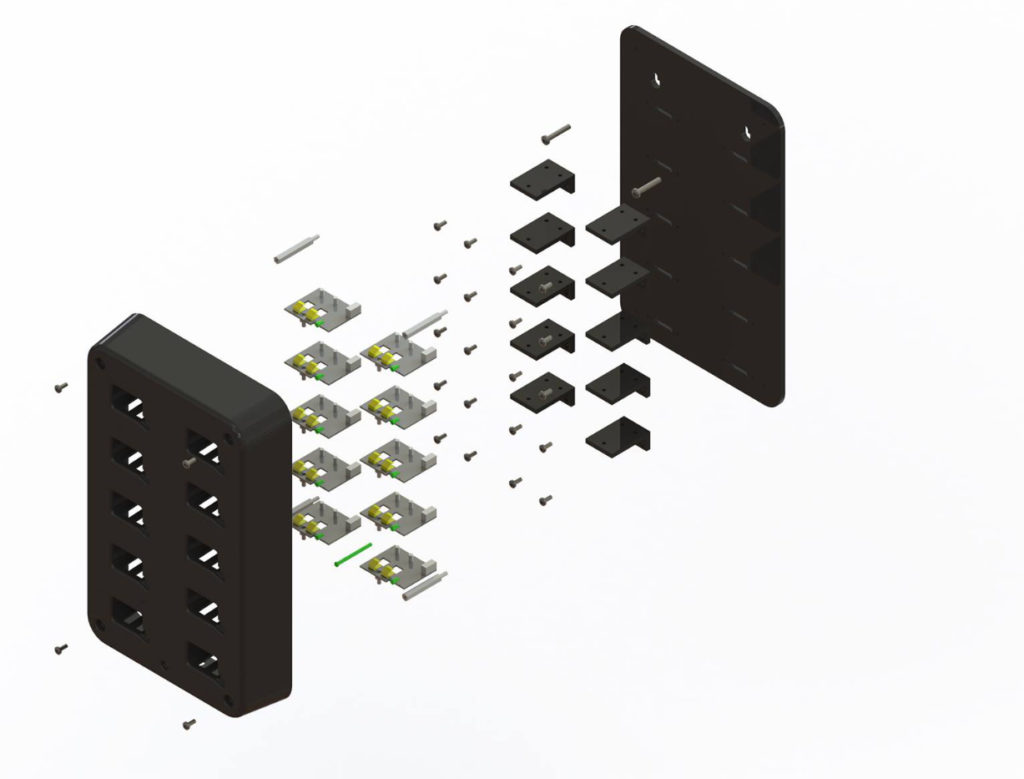

We analyse the component design of all new projects and apply our experience of ‘design for manufacture‘ to maximise mould ability, minimise second operations, reduce assembly time and simplify tooling – adding value at every stage, resulting in the ideal combination of material, mould, manpower, and machine for efficient and cost-effective production.

With nearly forty mechanical designers on staff HH Industrial can provide comprehensive design and technical support for your projects.

Whether your project needs Design for Manufacture (DFM) review or a complete concept realisation, our product development processes can provide the level of support you require.

Our design service is combined with a world-class prototype and pilot production facility to further reduce design and development lead times.

Once the design has been finalised, there is nothing better than to bring the component to life, and see it for real. We have close links with a number of partners who can provide support for the production of prototype parts using SLS, SLA, 3D Printing or casting from Silicon moulds, or aluminium tools for preproduction runs.

By letting the design department, manufacturing/ production engineering and marketing departments see the model at an early stage allows costly errors to be eliminated. Any mistakes can be rectified before expensive tooling has been made for full production whilst the models at this stage are relatively inexpensive.

HH Industrial offer an established sub-contract sourcing, assembly and finished product supply service.

Our customers trust HH Industrial’s Quality Systems to ensure their products are manufactured to their specified standards and from their specified materials.

With factories in Shenzhen and Dongguan totalling more than 10,000 square metres we have both the capacity and experience to help our customers get their products to market.

HH Innovations design and manufacturing processes benefit our customer base by providing speed and certainty through the development process assuring the results match the true needs of the customer’s requirements into production. If a true collaboration can be attained where trade-offs are understood at the design level, decisions are made in real time and implications are understood, iterations can be reduced allowing product plans to be realised meeting cost and time to market considerations.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |